Humans are learning new roles in manufacturing as they realign to work tandem with increasingly sophisticated robotic systems, which were extensively on display at Automate 2013. This robotics and vision show coincided with the industry supply-chain and distribution show ProMat 2013, held in Chicago Jan. 21-24.

More than 200 exhibitors were on display at McCormick Place including manufacturers of robots, camera and lighting systems, motors and drive technologies, as well as an array of systems integrators. The show offered industry professionals and fledgling engineers an up-close look at some of the newest technologies available. Click on the links below to take a tour of some things you might have missed.

Robotics smoothes tote loading

Pack Flow Concepts showed a robotic system that takes individual packs from a tote or case and places them efficiently in a delivery tote, using a robot from Universal Robots.

High-speed packaging robot from Fanuc that is especially suitable for food and beverage applications does up to 180 picks/min.

Robotic programming simplified

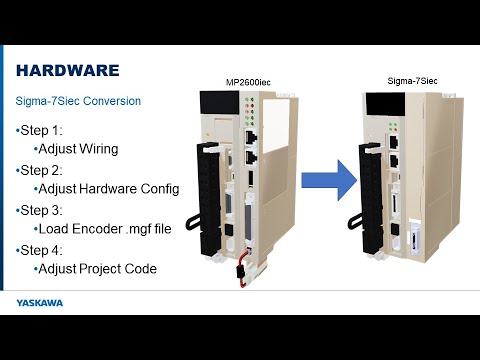

Labview library for a Yaskawa robot was on display at the National Instruments’ Automate 2013 booth, and the demo included the use of a Sick Ranger laser 3D camera.

The Motoman Robotics Div. of Yaskawa Americas featured a dual-head robotic picking system that handles up to 185 picks/min.

Small-footprint spiral conveyor

Slimline spiral conveyor from Ambaflex has a small footprint and can handle products on a 12” wide conveying surface.

Schneider’s Robotic cartoning and case-loading system uses a delta-style robot and a machine vision system to locate and pick items at speeds to 300/min.

Autovision 2.0 from Microscan has a feature called Microscan Link that permits communication internally as well as externally through Ethernet IP.

Eaton’s Smartwire is a control wiring solution that allows easier installation and commissioning of packaging machinery. It also opens up panel space in the control cabinet.

A five-sided scan tunnel from Cognex handles a conveyor speed of up to 650 ft/min to provide automatic ID solutions in the logistics industry.

轻量级、协作机器人designed by Universal Robots is meant to be used in close proximity with humans and can be moved around from position to position in the plant.

The SpanTech Transorter offers a unique way of sorting ultralight items or anything weighing up to about 55 lb.

Baxter is a $22,000 robot from Rethink Robotics that performs repetitive tasks at modest speeds. Force-sensing technologies make it extremely safe for operation around human beings.

Pallet-labeling system from Logopak, which includes an RFID option, prints and applies labels on one, two, or three sides of a pallet.