用户程序焊接参数可以作为工作点/ trim or amps/volts, along with up to four "Wave Controls" with allowable limits displayed from the process library in the Lincoln power source. Users can also program Lincoln's Production Monitoring process limits and define alarm and fault conditions from the robot's touch screen pendant display. Password protection has been added to different levels of control parameters for plant supervision. The interface has expanded from 32 to 200 weld profiles within the power source. Weld data from each weld can be displayed on the teach pendant, communicated via PLC signals and/or sent to a cloud database with Lincoln's CheckPoint function. The enhanced robotic interface allows full control of any processes in the power source library. It can also be used in tandem wire applications and optional process like Surface Tension Transfer (STT). The interface simplifies access to production monitoring features for improved quality and production control, and is scalable to all of Lincoln's new Robotic Power Wave models (R350, R500 and S700).

>>For more information on this product, clickhere

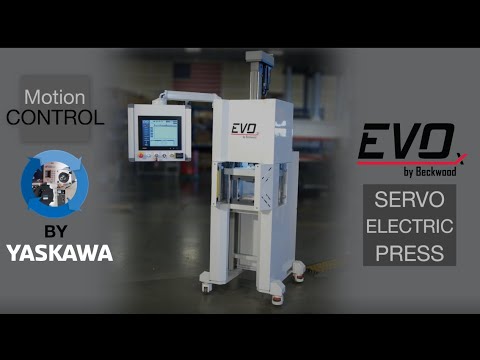

Yaskawa Motoman

www.motoman.com

937.847.6200